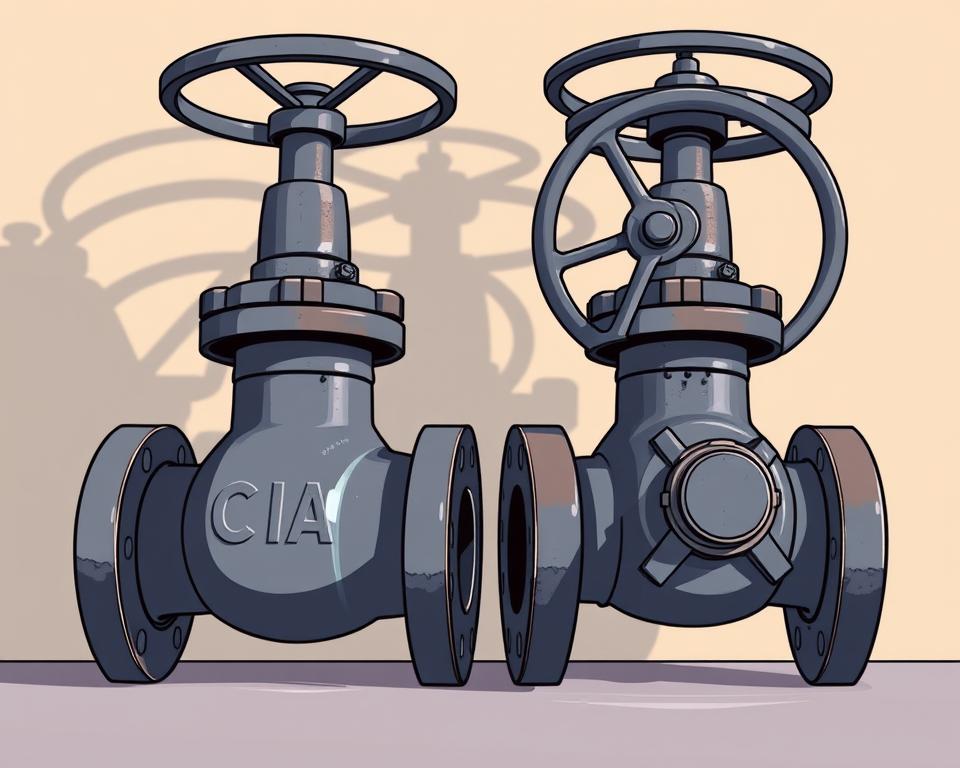

Cast Iron Gate Valves: Features, Benefits, and Uses

Might one quality valve shrink maintenance time and keep water networks running longer?

I make and supply Cast Iron Gate Valve Manufacturer at Yaxing Valve, and I back their performance and support for U.S. customers. This product line is built for long life in public water and light industrial applications.

Every valve combines a rugged cast-iron body, a precision-machined wedge guide, and simple handwheel operation. This yields trustworthy isolation, serviceable upkeep, and steady performance in buildings, fire mains, and utility distribution lines.

I partner with specifiers to accelerate submittals and provide clear data: sizes, connection types, pressure classes, and optional accessories. We retain cart and preference data (cookies) to make reorders simple.

When you want a practical replacement or budget-smart choice for new work, compare these cast-iron gate valve advantages against your current hardware to identify life-cycle gains and field fit.

Why I Trust Yaxing Valve Cast Iron Gate Valves for Reliable Flow Control

I personally validate each product at Yaxing Valve, so I can recommend our hardware with confidence for demanding U.S. jobsites.

Rugged cast-iron body engineered for industrial performance

Every valve features a strong cast-iron body that resists load-induced deformation. Metal-to-metal seating and precise machining ensure tight shutoff when customers need it most.

Flow-optimized design with minimal pressure loss

The internal path is optimized to lower turbulence and pressure loss. That helps pumps run more efficiently and lowers energy use across systems.

- I validate product dimensions and testing to align with common ANSI standards and internal checks.

- I refine stem/wedge/bonnet interfaces to reduce friction and maintain consistent torque over time.

- Body thickness targets balance durability with manageable handling weight.

- Documentation lists tests/standards so purchasing can wrap orders quickly.

| Feature | Primary Benefit | Tech Note |

|---|---|---|

| Cast-iron body | High rigidity | Stable geometry targets met |

| Flow-optimized gate | Less headloss | Improves pump efficiency |

| Finished stem/handwheel interfaces | Smoother operation | Stable torque for extended life |

| Spec documentation | Quicker approvals | ANSI-aligned test reports |

cast iron gate valves: Materials, Design Details, and Performance Essentials

I detail body, sealing, and stem choices so selection and ordering stay simple.

Body/Bonnet/Wedge Materials

I define the material stack-up plainly: a cast iron body and bonnet, a precision-machined wedge, and a metal-to-metal seat interface for dependable shutoff in water service and general industry.

Stem/Handwheel configurations

For compact layouts, I offer non-rising and inside-screw stem options. Screw thread forms and packing arrangements are fully documented.

Standards and performance limits

I publish qualified pressure and temperature ranges and align end connections to common ANSI standards to help engineers confirm fit without additional drawings.

- Interface between stem and handwheel tuned for consistent torque.

- Smooth internal geometry reduces headloss.

- Clear series IDs and submittal specs accelerate approvals.

| Component | Material / Type | Rated Limit | Remarks |

|---|---|---|---|

| Body & Bonnet | Cast iron | Up to 150 psi | ANSI flange sizing; weld/bolt options |

| Gate wedge | Precision-machined metal | −20°–180°F range | Metal-to-metal seating, low headloss finish |

| Operating stem | Non-rising / inside screw | — | Documented thread and packing in datasheet |

| Series | YX-100 and YX-200 | Sizes 2″–12″ | Clear part numbering for quick bids |

Applications, Installation, and Day-to-Day Operation

I help contractors and owners place these valves where they perform best in modern loops. My aim is to keep selection, installation, and checks straightforward so crews wrap up commissioning with no call-backs.

Use cases: waterworks, building systems, general industry

Use a full-bore unit where low restriction matters — long mains, service feeds, and bypass lines benefit the most.

Where vertical space is constrained, use non-rising or inside-screw stems in mechanical rooms and process loops.

Installation guidelines

During handling, protect the body, lift at rated points, and avoid stressing flanges. Verify end alignment before final torque to avoid leaks and distortion.

Select compatible gaskets, torque in a cross pattern, and space supports to prevent line sag.

Operation and maintenance notes

Position the handwheel for easy access and verify free movement after packing tweaks.

Perform periodic torque checks under pressure, inspect the wedge and packing, and confirm the pressure/temperature range against your media. Capture tag IDs in your account and link CMMS work orders.

| Area | Recommended Action | Timing | Result |

|---|---|---|---|

| Application selection | Use full-bore on mains; inside-screw/NRS in tight spots | Design phase | Less pressure loss and space efficiency |

| Handling/installation | Use lift points, align ends, torque in sequence | Installation | Avoids stress-related leaks |

| Operating checks | Verify handwheel feel; test under pressure | Commissioning & routine | Stable operation with reliable shutoff |

| Maintenance records | Tag valves and link to account/CMMS | Ongoing | Faster parts tracking and replacements |

Correct handling/commissioning extends service life and keeps Resilient Seated Gate Valve performing and looking like new.

Specify the Right Iron Gate Valve with Me at Yaxing Valve

Share line size, pressure expectations, and flow needs; I’ll match series/type to duty range and temperature.

I use a short checklist so submittals pass first review: end connections, inside screw or non-rising preference, and handwheel orientation. I also note stem handwheel and screw details for clear install guidance.

Check the image gallery for high-resolution views with layouts showing clearance and operator reach. Make an account to save specs, tag valves, and link drawings plus a one-page field PDF.

Reach out for a quick quote—I’ll confirm stock, lead times, series alternatives, and help you finish the order while you review the gallery. We only use cookies to keep your session and cart active.